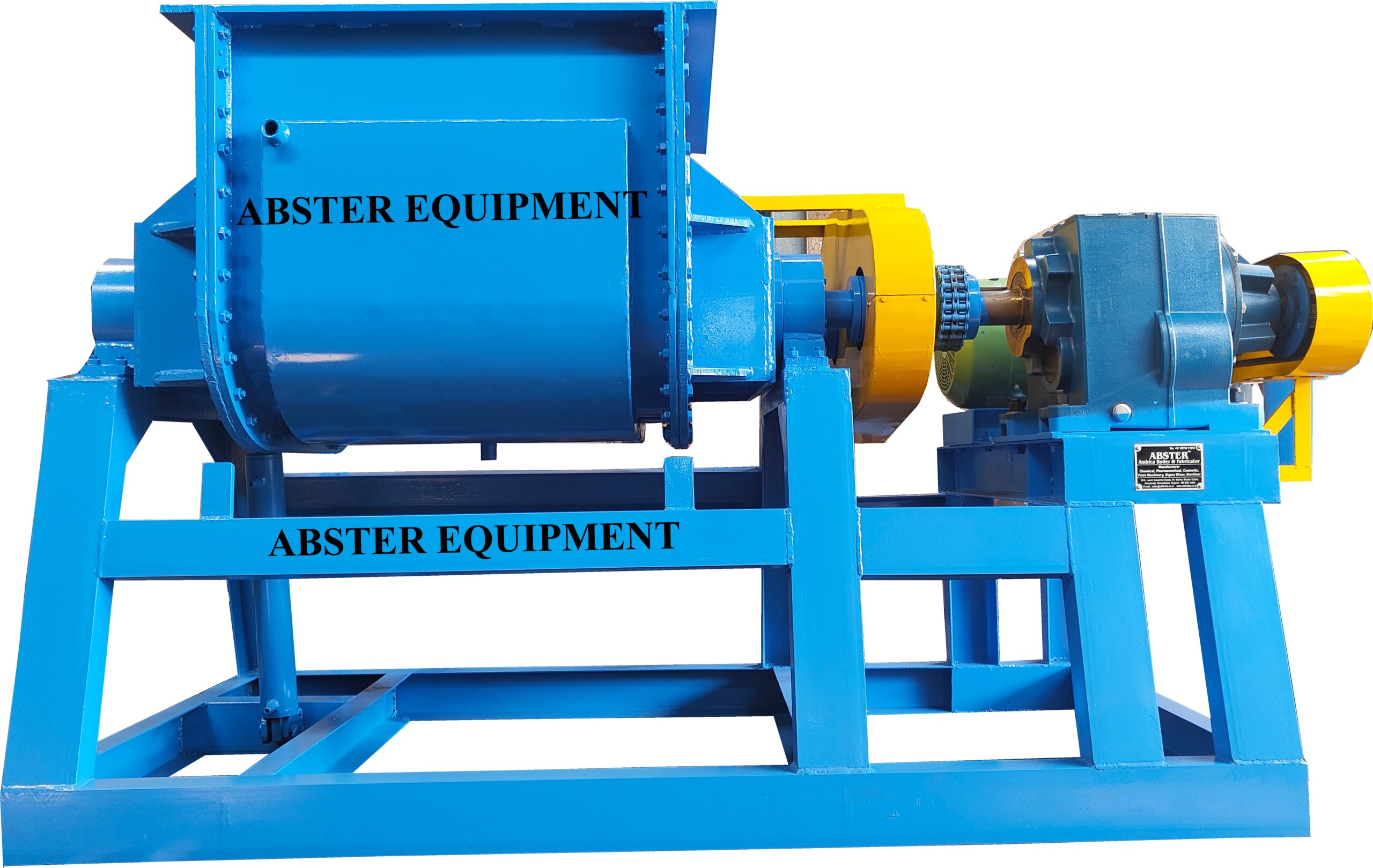

Reaction Vessel

Abster Equipment is designer and manufacturer of Reactors & Pressure Vessels custom made for Pharmaceuticals, chemicals, fertilizer, food, petro chemical and other allied industries. Abster reaction vessel, Pressure vessel & Reactor as per international codes & standards such as ASME, IS and SS etc. We are providing Reactor systems with external and internal coils for heating and cooling applications.

All material procured from reputed suppliers who can deliver material of approved and recognized steel manufacturers with test certificates to give best quality of Reactor & pressure vessel to end user. DPT/NDT testing methods used to check welding quality of Pressure vessels & Reactors manufacturer.

Description of Reactor Vessel

We are recognized firm engaged in manufacturing extremely efficient Reactor Vessel that is the central component of the reactor coolant system and which is sturdily steel constructed by the skilled professionals of our company. The Reactor Vessels designed and developed by us are widely used in commercial nuclear power plant, pharmaceutical industries, chemical plants, etc.

Reaction vessels are at the heart of a chemical plant. They are where the chemical Changes and reactions take place. Powders or liquids may be poured into reaction vessels using large funnels, called hoppers, connected to the top of the vessel.These stainless steel liquid mixing tanks are highly efficient to use with its robust mixing structure for homogeneous mixing of different chemicals and ingredients.

Abster Equipment is an extremely efficient Reactor Vessel Manufacturer and Supplier company from Ahmedabad, Gujarat, India.

Applications :-

The reactor vessel used in the first commercial nuclear power plant, Fit for pharmacy, chemical industry, dye, resin and food Industry, It can be widely used in Liquid Resin, Rubber, Pesticide, Glue, Dye, Medicines. Food, Pharma, Chemical, Minerals, Guar Gum, Starch, Pigment Colors & etc.

Stainless Steel Reactor Tank Selection Guide

Determine Capacity: Select the appropriate tank capacity based on specific production needs.

Choose Material: Select 304 or 316L stainless steel based on the properties of the materials being processed.

Design Pressure: Specify the working pressure requirements if pressure resistance is needed.

Heating and Cooling Requirements: Choose the appropriate heating or cooling method (steam, electric, thermal oil, or cooling jackets) based on the process requirements.

Agitator Type: Select the suitable agitator type (anchor, paddle, propeller, or turbine) based on the viscosity and nature of the materials being mixed.

Special Requirements: If additional features like insulation, specific control systems, or extra accessories are needed, specify these in advance.

Accessory Selection: Choose necessary accessories such as thermometers, pressure gauges, and CIP systems based on specific usage requirements.

SPECIFICATION

| Capacity | 50 L TO 20,000 LITER |

| Chemical Reactor | Chemical Reactor , With Agitator , Jacketed & Limpet . |

| Reactor Type | Both Dish End , Motor and Gear box , Inside Agitator for Mixing Material , Bottom discharge connection Vertical outer heating limpet and jacketed |

| Usage/Application | Reaction , Mixing or Blending Row Material |

| Mixing Material | Chemicals / Oils / Lubricant / Liquid Syrup / Sugar Syrup / Wax Melting /Engine Oil |

| Material of Construction | Stainless Steel ,Mild Storage |

| Orientation | Vertical Orientation |

| Shape | Round |

| Tank Diameter | As Per Your Requirement |

| Electric Heater | Single Phase or Three Phase |

| Temperature Controller | Automatic or PLC Operated , Ph Indicator |

| Mixing Speed (RPM) | Variable , Speed Up And Down As Per Requirement |

| Finishing Type | Matt Type ,Mirror Finishing |

| Heating and Cooling System | YES |

| Temperatures Range | 30 TO 250 Degree |

| Vacuum | Yes |

| Cooling Coil | Internal Coil ,Outer Limpet , Outer Jacketed |

| Outer | Heating coil or jacket |

| Resting | Leg or Resting Lug |

Application Industry

- Pharmaceutical industry

- Chemical industry

- Food and beverages industry

- Petro-chemical industry

- Resins industry

- Polymers industry

- Coatings industry

- Adhesives industry

- Agricultural industry

- General chemicals industry

- Plastics industry

- Rubber industry

- Herbal Extractor

Send Inquiry

Categories

Recent Post